×

- Live Chat

- 1-888-984-2011

My Garage

My Account

My Cart

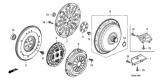

Genuine Honda Fit Pressure Plate

Clutch Pressure PlateEnter your vehicle info to find more parts and verify fitment

- Select Vehicle by VIN

- Select Vehicle by Model

Select by VIN

orEnter your VIN for the most accurate results.Enter your VIN for the most accurate results.

Select by Model

-- Select Model --

-- Select Year --

-- Select Body & Trim --

-- Select Emission & Transmission --

3 Pressure Plates found

Honda Fit Disk, Pressure

Part Number: 22300-RE1-005- Other Name: Pressure Plate

$181.83 MSRP: $259.02You Save: $77.19 (30%)Honda Fit Disk, Pressure

Part Number: 22300-RB0-005- Other Name: Pressure Plate

$256.29 MSRP: $365.09You Save: $108.80 (30%)Honda Fit Disk, Pressure

Part Number: 22300-PWA-305- Other Name: Pressure Plate

- Replaces: 22300-PWA-005

$268.85 MSRP: $382.98You Save: $114.13 (30%)

Honda Fit Pressure Plate Parts Questions & Answers

- Q: How to remove and install Clutch Disc,Flywheel and Pressure Plate on Honda Fit?A: The clutch parts are best reached when the transaxle is pulled out and if the powerplant is pulled out for a major rebuilding the clutch should at least be checked for wearing and any worn out part replaced because the clutch parts are cheap and therefore it is advisable to replace them when the engine transaxle is pulled out unless it is new or in very good condition. For removing the clutch disc some amount of support is required, for that clutch alignment tool should be inserted through the clutch disc hub and some alignment mark should also be made to match the pressure plate and flywheel during the clutch reinstallation. The pressure plate to flywheel bolts should be slackened by turning an amount gradually in a diagonal sequence until no spring tension is noticed; this will allow the removal of the pressure plate and clutch disc. To change the Release Bearing, the release fork boot must be taken off, and to change the release fork the top bolt must be undone and the release fork can be pulled out of the transaxle for bearing replacement and hi-temp grease needs to be put on all the pivot points before reassembly. The clutch driven plate assembly should be inspected for signs of wear and tear; the general state of the flywheel and the clutch disc lining and the release bearing should also be investigated for signs of severe wear and tear; the wisdom given before is to replace the clutch disc if one is in doubt. The Pilot Bearing should be lubricated and should be rotated freely with minimum end-play while tightening the nuts the pressure plate should be examined for signs of wear or heat and if damaged, should be replaced. In installation, the outer surfaces of the flywheel and pressure plate are required to be cleaned, though the clutch disc should be placed in the correct place using alignment tool, after which the pressure plate-to-flywheel bolts are to be tightened in a star-like pattern in order to avoid distortion. When alignment is correct, the bolts should be tightened to specified torque then removal of alignment tool, and the tool should fit smoothly. Last of all the transaxle and all the components which have been removed should be replaced, and all screws and bolts should be tightened to their respective torque.