×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

Genuine Honda Accord Wheel Seal

Wheel Axle Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Wheel Seals found

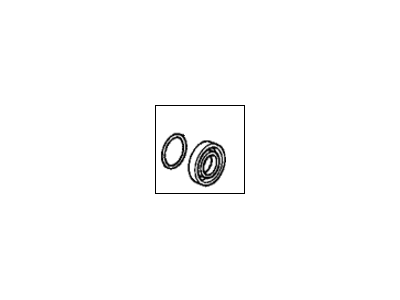

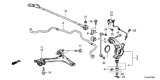

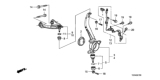

Honda Accord Ring, Front Knuckle

Part Number: 44348-TA0-A00$25.05 MSRP: $35.38You Save: $10.33 (30%)

Honda Accord Wheel Seal

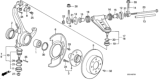

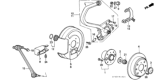

Wheel seal is an important component in the Honda Accord automobiles since it protects the wheel bearing and hub from contamination by dust, rocks or any debris. Its role is mainly to minimize the chances of the lubricant spilling out while at the same time excluding dirt from penetrating the wheel bearing assembly that can be destructive. Like the previous years, different Wheel Seals have been used on the Honda Accord such as front and rear inner and outer seals. These seals are produced using quality materials and come in standard sizes and from some of the leading manufacturers such as Motorcraft, Beck Arnley and Timken. Periodical check up is again a very important aspect to determine whether the Wheel Seal has developed any leakages or cracks as this will lead to heat build up and brittleness which will really degrade the performance of the Honda Accord.

In search of affordable OEM Honda Accord Wheel Seal? Consider browsing through our extensive inventory of genuine Honda Accord Wheel Seal. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Accord Wheel Seal Parts Questions & Experts Answers

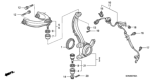

- Q: How can driveaxle oil seals be replaced to prevent oil leaks on Honda Accord?A:Oil leaks appear to be common on the basis of used wheel seals which are fairly easy to replace since the repair can usually be done without the removal of the transaxle from the car. Wheel seals are placed at the sides of the transaxle since the driveaxles are fixed there. If there is an observation of leakage at the seal, the vehicle must be raised and supported on jackstands; when the seal is leaking, a greasy substance will be noticed on the sides of the transaxle and below the seal. First, it is necessary to demount the driveaxles, while the seal is extracted with a screwdriver or a prybar inserting its tip behind the seal and pry it out from the transaxle bore. If these tools do not suffice and the seal is not easily removed, a specific seal removal tool, which can be bought from an auto parts store, will have to be utilised. In fitting the new seal, one can use a seal driver or a big deep socket which is slightly smaller than the outer diameter of the seal as the drift, one sees to it that the new seal is driven squarely into the bore and that it bottoms fully. Using transaxle lubricant, refer to step 4, carefully cover the seal lip without damaging it, this shall be done before installation of the driveaxles.

Related Honda Accord Parts

Browse by Year

2017 Wheel Seal 2016 Wheel Seal 2015 Wheel Seal 2014 Wheel Seal 2013 Wheel Seal 2012 Wheel Seal 2011 Wheel Seal 2010 Wheel Seal 2009 Wheel Seal 2008 Wheel Seal 2007 Wheel Seal 2006 Wheel Seal 2005 Wheel Seal 2004 Wheel Seal 2003 Wheel Seal 1989 Wheel Seal 1988 Wheel Seal 1987 Wheel Seal 1986 Wheel Seal