×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

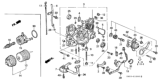

Genuine Honda Odyssey Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Oil Pumps found

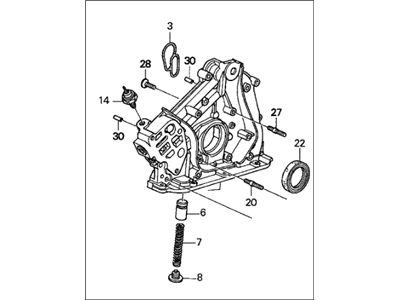

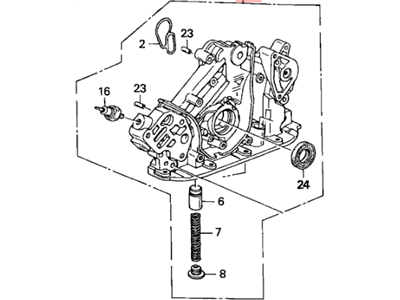

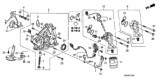

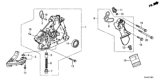

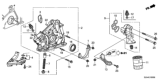

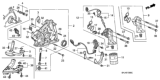

Honda Odyssey Pump Assembly, Oil (Yamada)

Part Number: 15100-RCA-A03$222.29 MSRP: $316.65You Save: $94.36 (30%)

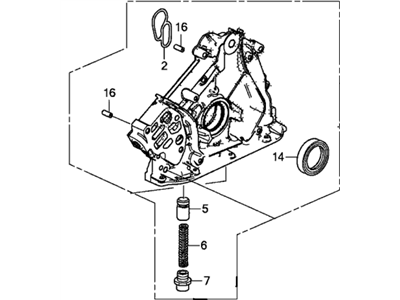

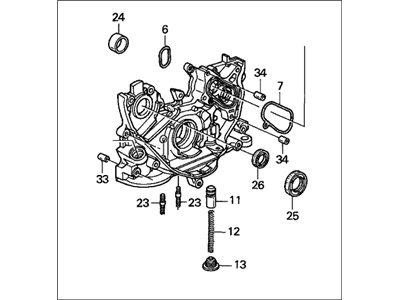

Honda Odyssey Pump Assembly, Oil

Part Number: 15100-5G0-A01$62.80 MSRP: $88.70You Save: $25.90 (30%)

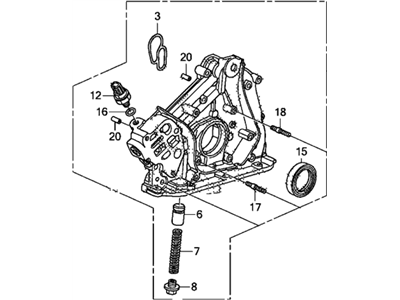

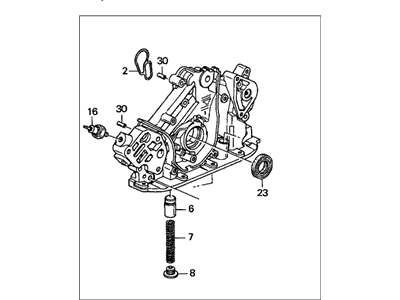

Honda Odyssey Pump Assembly, Oil

Part Number: 15100-R70-A02$278.16 MSRP: $396.23You Save: $118.07 (30%)

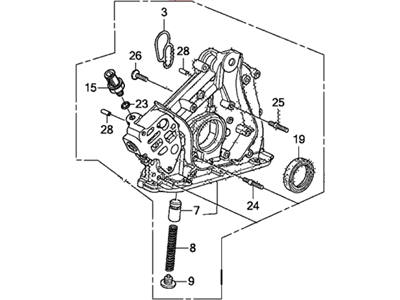

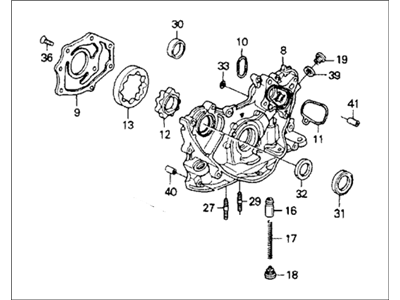

Honda Odyssey Pump Assembly, Oil (Yamada)

Part Number: 15100-R72-A02$244.45 MSRP: $348.22You Save: $103.77 (30%)

Honda Odyssey Pump Assembly, Oil (Aisin)

Part Number: 15100-P8F-A02$364.42 MSRP: $519.12You Save: $154.70 (30%)

Honda Odyssey Pump Assembly, Oil (Yamada)

Part Number: 15100-P8E-A01$339.03 MSRP: $482.95You Save: $143.92 (30%)

Honda Odyssey Oil Pump

The Oil Pump in Honda Odyssey vehicles is important for efficient working of internal combustion engine in a vehicle. It sprays oil under pressure on the bearings, pistons, cam shaft and also serves as hydraulic oil for some micro controllers. The Honda Odyssey usually employs mechanical oil pumps that are usually driven by crankshaft or camshaft which are always reliable. During the production of the Honda Odyssey over the years up to the model currently in use different oil pumps include, gear, trochoid and vane oil pumps. It effectively pumps the oil from the sump, filters it then circulate the oil to parts of the engine as required while the correct oil pressure is crucial for the efficient running of the engine is well maintained. Maintenance, such as oil and filter change, is compulsory in order to avoid blockage of the system as well as to enhance the performance of the Honda Odyssey's engine.

In search of affordable OEM Honda Odyssey Oil Pump? Consider browsing through our extensive inventory of genuine Honda Odyssey Oil Pump. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Odyssey Oil Pump Parts Questions & Experts Answers

- Q: How do you remove and install the Oil Pump on Honda Odyssey?A:To remove the Timing Belt, the crankshaft sprocket and the idler pulley, one has to, remove the crank shaft position sensor, the Oil Pan and the oil pick-up screen, and if present, the oil level probe. Then, loose the oil filler adapter housing NTEC solenoid assembly from the front of the oil pump after which loosen the bolts to come off the oil pump housing from the engine if necessary use screwdriver to pry between the main bearing cap and the pump housing. For inspection, the pump cover can be removed using a large Phillips screwdriver by unscrewing the screws at the rear of the housing and lifting off the cover to inspect the pump rotors and check for wear or damage by using feeler gauges and if the pump is found wanting, then it should be replaced. Remove any old sealant on the pump body and the engine block and use a scraper on it but be careful not to scratch the aluminum. For installation, remove the old crankshaft oil seal and coat the new one with multi-purpose grease, whereby the seal lip should be greased, fill the pump cavity with petroleum jelly and fix the cover with the help of the thread-locking compound and tighten the screws evenly in a criss-cross manner. Wipe down the gasket surfaces with acetone or lacquer thinner; coat the oil pump flange and the bolts required with the anaerobic sealant; the parts should be joined within 5 minutes of applying the sealant; replace the O-rings wherever necessary. Crank the oil pump drive rotor to the crankshaft, put in the pump, organize the mounting bolts that had been removed earlier and tighten up anew in a criss-cross manner. Replace the O-ring on the oil pick-up screen and snugly tighten the fasteners in position, then all other components in the reverse manner. The curing of the sealant takes 20 minutes after which oil is can be introduced, the engine can be started and the oil leaks and pressure checked, rechecking the engine oil level after operation.

Related Honda Odyssey Parts

Browse by Year

2026 Oil Pump 2025 Oil Pump 2024 Oil Pump 2023 Oil Pump 2022 Oil Pump 2021 Oil Pump 2020 Oil Pump 2019 Oil Pump 2018 Oil Pump 2017 Oil Pump 2016 Oil Pump 2015 Oil Pump 2014 Oil Pump 2013 Oil Pump 2012 Oil Pump 2011 Oil Pump 2010 Oil Pump 2009 Oil Pump 2008 Oil Pump 2007 Oil Pump 2006 Oil Pump 2005 Oil Pump 2004 Oil Pump 2003 Oil Pump 2002 Oil Pump 2001 Oil Pump 2000 Oil Pump 1999 Oil Pump 1998 Oil Pump 1997 Oil Pump 1996 Oil Pump 1995 Oil Pump