×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

Genuine Honda Del Sol Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Brake Lines found

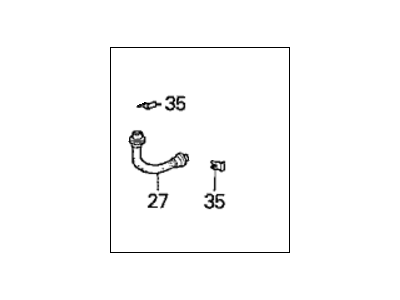

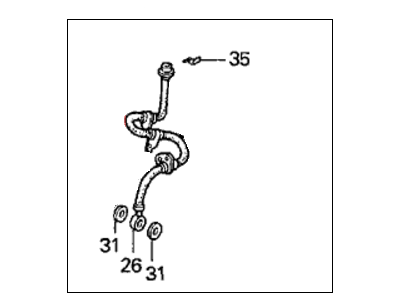

Honda Del Sol Hose Set, Right Rear Brake

Part Number: 01466-SR3-020$24.26 MSRP: $34.29You Save: $10.03 (30%)Honda Del Sol Hose, Left Rear Brake (Nichirin)

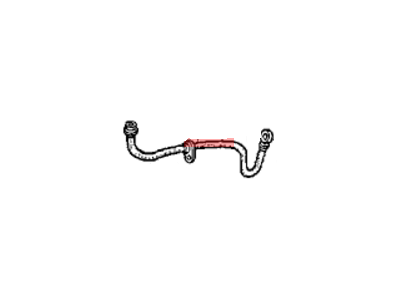

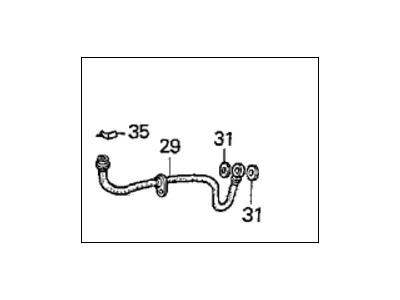

Part Number: 46431-SR3-937$25.61 MSRP: $36.16You Save: $10.55 (30%)Honda Del Sol Hose, Right Rear Brake (Nichirin)

Part Number: 46430-SR3-937$25.61 MSRP: $36.16You Save: $10.55 (30%)Honda Del Sol Hose, Right Front Brake (Meiji)

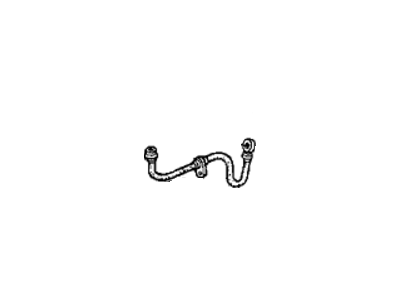

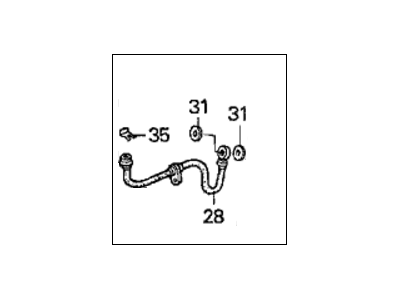

Part Number: 46410-SR3-004$47.92 MSRP: $67.68You Save: $19.76 (30%)Honda Del Sol Hose, Right Front Brake (Nichirin)

Part Number: 46410-SR3-003$47.92 MSRP: $67.68You Save: $19.76 (30%)

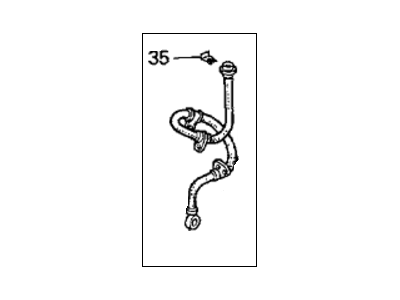

Honda Del Sol Hose Set, Left Front Brake

Part Number: 01465-SR3-N02$79.33 MSRP: $112.05You Save: $32.72 (30%)

| Page 1 of 2 |Next >

1-20 of 33 Results

Honda Del Sol Brake Line

In search of affordable OEM Honda Del Sol Brake Line? Consider browsing through our extensive inventory of genuine Honda Del Sol Brake Line. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Del Sol Brake Line Parts Questions & Experts Answers

- Q: How often should flexible hoses connecting steel brake lines be inspected for damage on Honda Del Sol?A:The flexible hoses which connect the steel brake lines with the rear brakes and front calipers must be checked for cracks, chafing, leaks, blisters, etc every six months. Original equipment and aftermarket steel and flexible brake lines can be purchased in part store, service parts department from an auto dealer among other auto parts stores. When putting in the brake line it is critical that not less than 3/4 of an inch between the line and other parts that are movable or vibrate. To remove a hose and line, one has to use a flare-nut wrench to loosen a brake line-to-hose fitting and undo the clip as well as shifting the hose out of the bracket. Where two hoses mating is involved, you should not use impact wrenches on the hose fittings but normal wrenches only, after undoing the two hoses, ensure that the two are not twisted or strained in any way. Most steel brake lines are clipped in place along their length and these clips, which should first be removed to enable the withdrawal of a fixed brake line, should always be reapplied or replaced if required because they assist in preventing vibration which may ultimately cause failure of the brake line. When you have to replace brake lines, use the correct one and never use copper tubing and get the steel brake lines from dealer or auto parts store. Make sure that a steel line does not have any of its portion in close contact with moving or hot parts and such part of the steel line is firmly fixed on the brackets. Following the installation of the master cylinder, check the brake master cylinder fluid level, put in some more fluid if needed, do a brake bleeder, and examine the brakes and then take the vehicle for a spin to check on the brakes in traffic.