×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

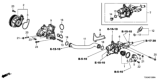

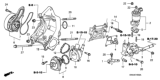

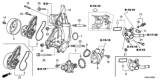

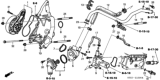

Genuine Honda CR-V Water Pump

H2O Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Water Pumps found

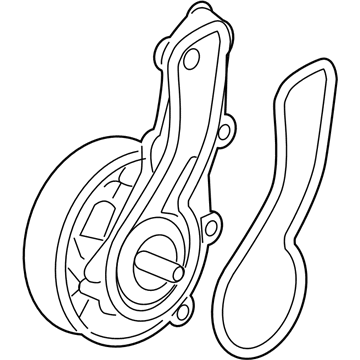

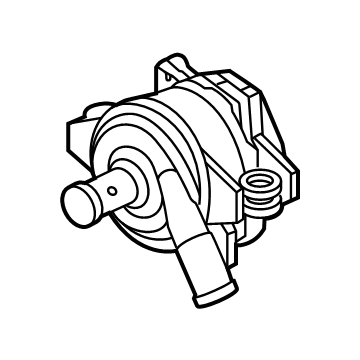

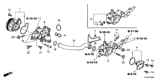

Honda CR-V Pump Complete, Water

Part Number: 19200-5A2-A01$121.34 MSRP: $177.40You Save: $56.06 (32%)

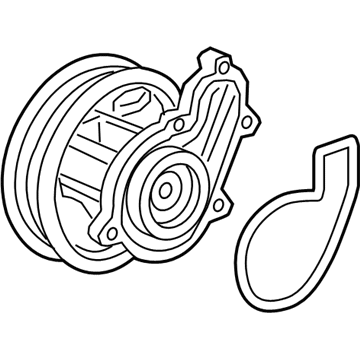

Honda CR-V Pump Complete, Water

Part Number: 19200-59B-003$118.65 MSRP: $173.47You Save: $54.82 (32%)

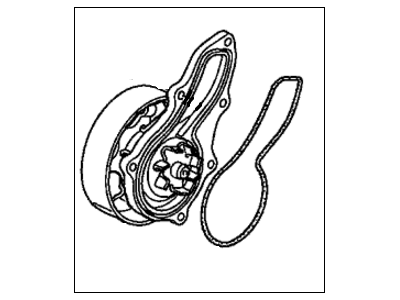

Honda CR-V Water Pump (Yamada)

Part Number: 19200-P75-003$189.69 MSRP: $270.22You Save: $80.53 (30%)

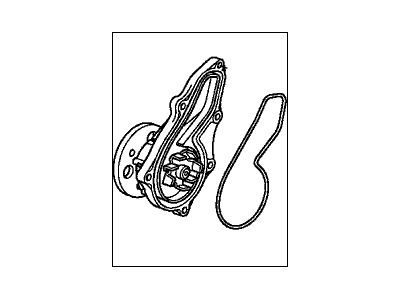

Honda CR-V Pump Complete, Water

Part Number: 19200-RX0-A01$120.09 MSRP: $171.07You Save: $50.98 (30%)

Honda CR-V Pump Complete, Water

Part Number: 19200-R5A-A01$117.68 MSRP: $167.63You Save: $49.95 (30%)

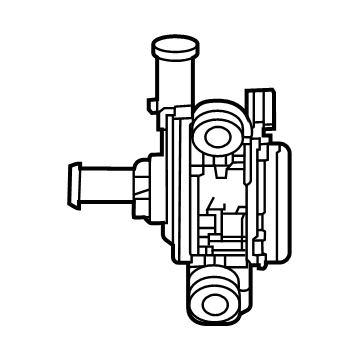

Honda CR-V Water Pump, Electric

Part Number: 1J200-5K1-A01$216.17 MSRP: $307.93You Save: $91.76 (30%)Honda CR-V WATER PUMP, ELECTRIC

Part Number: 1J200-6GS-005$273.29 MSRP: $389.30You Save: $116.01 (30%)

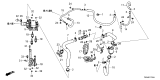

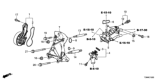

Honda CR-V Water Pump

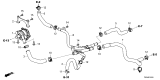

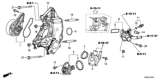

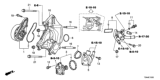

The Water Pump in Honda CR-V vehicles is an important component which keeps the engine temperature constant by circulating water coolant in the engine and its cooling system. The Water Pump has a very basic design: An impeller puts the coolant through the force of centrifuge as the vehicle works to effectively absorb heat. Different styles of Water Pumping may have been used in the various model years of Honda CR-V, however the basic working remains the same. But where there is undue stress on the part of the bearing or on the impeller or where there are complications such as loose gaskets, spongy situations, or rust formation, replacement becomes inevitable. A malfunctioning Water Pump can lead to serious cooling system failures, may cause engine overheating and that is why this part plays a significant role for fuel efficient Honda CR-V.

In search of affordable OEM Honda CR-V Water Pump? Consider browsing through our extensive inventory of genuine Honda CR-V Water Pump. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda CR-V Water Pump Parts Questions & Experts Answers

- Q: How to replace a water pump on Honda CR-V?A:Remove the cable which was connected to the negative terminal of the battery. Flush out the cooling system as a whole and keep the coolant, if the coolant is comparatively new or good, and do note the below mentioned Caution. Detach the drive belts, and for 2.4 L engines, unscrew the drivebelt tensioner and idler pulley together with the bracket. Take out the alternator, and for the 1.8L engines, you need to take out the water pump pulley bolts and the pulley-loosening while holding the water pump pulley and then remove the three mounting bolts. Take off the drivebelt tensioner and for 2.4L engines ,remove the crankshaft pulley if there is. Take out the bolts and pull off the water pump from the engine and inspect the impellers for signs of rot and filing off fins. Free the bolt threads and threaded holes in the engine for corrosion and sealants. Ascertain that the new pump corresponds to the old one in all factors by comparing them to each other. Clean all old gasket sealant and O-ring from the engine block and then clean both the surfaces of the mating engine and the new water pump by wiping on brake system cleaner. Coat lightly with RTV sealant the O-ring groove of the new pump, and then place carefully a new O-ring into the groove. Screw the bolts in the pump and fix it to the engine with finger tightened bolts the bolt threads should be coated with RTV sealant and the dowel pins must be in original position. Loosen some of the bolts and then process of tightening should be done gradually to the recommended torque but not exceeding this as this may cause distortion of the pump. Replace all components that were dismantled for the access to the pump, fill the cooling system, and adjust drivebelt tightness. Last but not the least, connect the battery, start the engine and check for any kinds of leakages.

Related Honda CR-V Parts

Browse by Year

2026 Water Pump 2025 Water Pump 2024 Water Pump 2023 Water Pump 2022 Water Pump 2021 Water Pump 2020 Water Pump 2019 Water Pump 2018 Water Pump 2017 Water Pump 2016 Water Pump 2015 Water Pump 2014 Water Pump 2013 Water Pump 2012 Water Pump 2011 Water Pump 2010 Water Pump 2009 Water Pump 2008 Water Pump 2007 Water Pump 2006 Water Pump 2005 Water Pump 2004 Water Pump 2003 Water Pump 2002 Water Pump 2001 Water Pump 2000 Water Pump 1999 Water Pump 1998 Water Pump 1997 Water Pump