×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

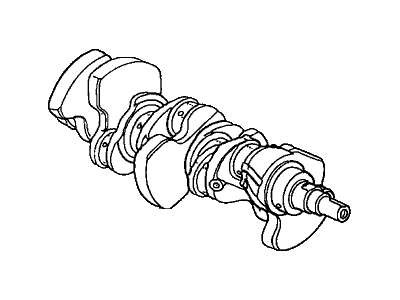

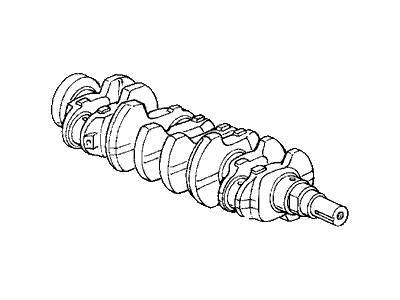

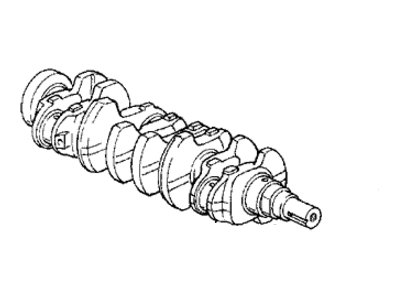

Genuine Honda Odyssey Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Crankshafts found

Honda Odyssey Crankshaft

In search of affordable OEM Honda Odyssey Crankshaft? Consider browsing through our extensive inventory of genuine Honda Odyssey Crankshaft. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Odyssey Crankshaft Parts Questions & Experts Answers

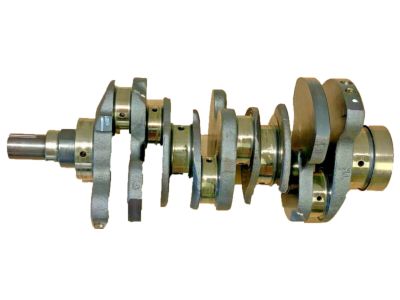

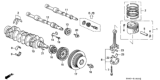

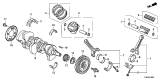

- Q: How can the crankshaft be removed and installed on Honda Odyssey?A:The crankshaft is only removed after the removal of the engine, which in turn requires removal of the driveplate, crankshaft pulley, timing bell, oil pan, oil pump body, oil filter, and piston/Connecting Rod assemblies where applicable. But before removal, it is advisable to use a dial indi-cator to compare the end play of the crankshaft. Push the crankshaft to the rear and read the indicator and then push it to the front to take the reading which should range from 0.0030.010 inch from the zero gauge (0.0760.254 mm). Feelers can be used in checking clearance in case a dial indicator cannot be used in carrying out the exercise. Turn the main bearing cap bolts on a clockwise and anticlockwise pattern slowly and gently knock the caps, using a soft-faced hammer; then carefully lift the crankshaft out without damaging bearing inserts. For installation, guarantee that the engine block and crankshaft are clean, and their condition analyzed. Turn the block over, undo the main bearing caps and clean the bearing faces. Machine new upper main bearing inserts, make sure there are oil holes and place lower inserts in the caps. Plastigage used to check the oil clearance and make sure that it is within its standard measurements. If not, check for cleanliness and decide which size of bearing you want for your machine. After Plastigage mop up, apply little grease on the bearing areas, re-position the crankshaft and put the caps labeled 'FRONT' in front. Tighten the bolts in the right order and measure and verify the crank end play and then rotate the crankshaft to and fro. Last but not the least, fit the new rear main oil seal.

Related Honda Odyssey Parts

Browse by Year

2026 Crankshaft 2025 Crankshaft 2024 Crankshaft 2023 Crankshaft 2022 Crankshaft 2021 Crankshaft 2020 Crankshaft 2019 Crankshaft 2018 Crankshaft 2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft 1996 Crankshaft 1995 Crankshaft