×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

Genuine Honda Prelude Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

30 Camshafts found

Honda Prelude Camshaft, Exhuast

Part Number: 14121-P13-000$379.68 MSRP: $540.86You Save: $161.18 (30%)

| Page 1 of 2 |Next >

1-20 of 30 Results

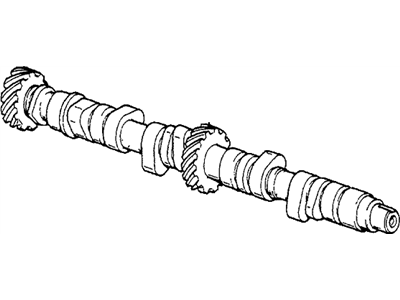

Honda Prelude Camshaft

The camshaft in vehicles is found in Honda Prelude particularly in the valvetrain, its main function is to control the intake and exhaust valves in the engine. This mechanism use lobes in the shape of a cam to transform rotational motion into reciprocal one, constantly synchronised with the pistons by means of a chain or belt. Over the years, the models of Honda Prelude have had two types of operations, namely the single overhead camshaft (SOHC) and the double overhead camshaft (DOHC) with some models having the tricks of Variable Valve Timing and Lift Electronic Control (VTEC). The camshaft is made from such parts like the cast iron and billet steel and it determines the engine RPM range among other factors. Some characteristics that include duration, lift and timing have a direct impact on power or the rev and the idle. The Honda Prelude coupe differs significantly from the original model and it is notable that the period of activity of the automaker has witnessed a lot of developments in the effective design of camshaft, which has become a vital part of the car and contributed to the car success and attracting buyers.

In search of affordable OEM Honda Prelude Camshaft? Consider browsing through our extensive inventory of genuine Honda Prelude Camshaft. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Prelude Camshaft Parts Questions & Experts Answers

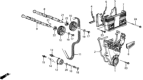

- Q: How to inspect and replace a camshaft on Honda Prelude?A:The camshaft turns in journals; the caps of the camshaft are incorporated in the Cylinder Head, and does not include bearings between the camshaft and the head. If one of the journals is damaged, it is necessary to change the head, and the reasons for the failure must be determined. First, record the radio security code and the stations tuned in by putting the broadcast channel and the presets in writing then remove the negative terminal of the battery. The spark plug wires should be disconnected, the valve cover and Timing Belt should also be removed. The Rocker Arm lock nuts and adjusting screws are to be loosened and thereafter camshaft bearing caps or holder plates are to be removed and camshafts are to be taken out carefully. Pull of the rocker arms and record their positions and wear and tear if any. During installation ensure that new O-rings, seals and gaskets are used. It is recommended that the camshaft bearing caps are cleaned and inspected before the camshaft is lubricated on the lobes and journals before the camshaft bearing caps are installed and fastened to 86 inch lbs. in sequence. The camshafts should be set for the top dead centre of the No. 1 piston and the holes should be aligned and a 5mm pin punch inserted. Insert the keys into the camshaft keyways, fit the pulleys and again tighten the retain bolts to 27 ft. lbs. Bolt the timing belt in place while setting the valve clearance; torque the valve cover nuts to 86 inch lbs. Tap the spark plug wires if any and reconnect the negative terminal of the battery, afterwards, enter the radio security code. For inspection, usually the camshaft needs to be cleaned by degreasing the camshaft, the oil holes must be cleaned, the cam lobes and the bearing journals have to be inspected for excessive wear. Any questionable lobe will require checking all the lobes; if the journal is worn or the lobe, then the camshaft has to be replaced. If the lobes and journals on the camshaft and journals on the camshaft lobes look good, the straightness should be checked with V-blocks and dial indicator, reinstalling the camshaft if it deviates more than 0.001 in. Camshaft lobe lift should then be measured with a micrometer and if the exhaust and intake lobes do not measure the same then the camshaft will have to be reground or changed.

Related Honda Prelude Parts

Browse by Year

2026 Camshaft 2001 Camshaft 2000 Camshaft 1999 Camshaft 1998 Camshaft 1997 Camshaft 1996 Camshaft 1995 Camshaft 1994 Camshaft 1993 Camshaft 1992 Camshaft 1991 Camshaft 1990 Camshaft 1989 Camshaft 1988 Camshaft 1987 Camshaft 1986 Camshaft 1985 Camshaft 1984 Camshaft 1983 Camshaft 1982 Camshaft 1981 Camshaft 1980 Camshaft 1979 Camshaft