×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

Genuine Honda Prelude Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

45 Cylinder Heads found

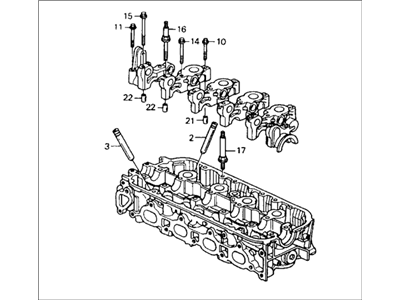

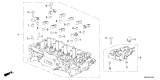

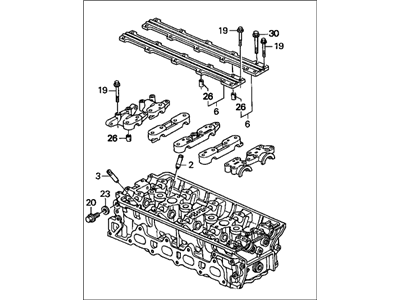

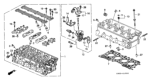

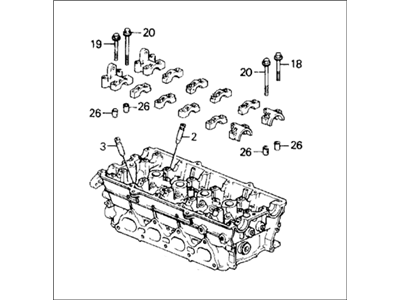

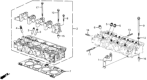

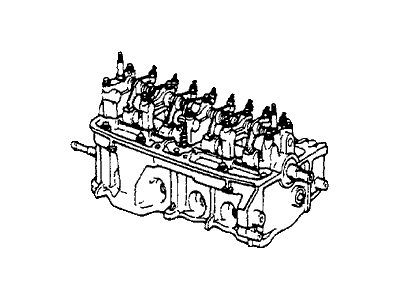

Honda Prelude Cylinder Head Assembly

Part Number: 12100-PT3-A01$1307.49 MSRP: $1741.58You Save: $434.09 (25%)Honda Prelude General Assembly, Cylinder Head

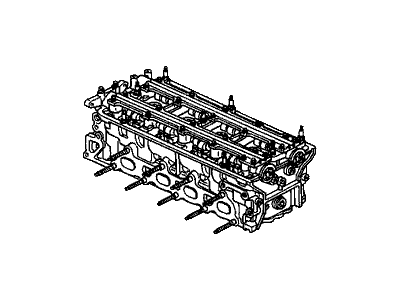

Part Number: 10003-P5M-A21$2618.58 MSRP: $3487.97You Save: $869.39 (25%)Honda Prelude HEAD ASSY-, CYLN

Part Number: 12100-69F-A00$830.37 MSRP: $1086.48You Save: $256.11 (24%)

| Page 1 of 3 |Next >

1-20 of 45 Results

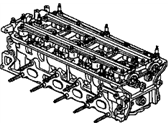

Honda Prelude Cylinder Head

In search of affordable OEM Honda Prelude Cylinder Head? Consider browsing through our extensive inventory of genuine Honda Prelude Cylinder Head. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Prelude Cylinder Head Parts Questions & Experts Answers

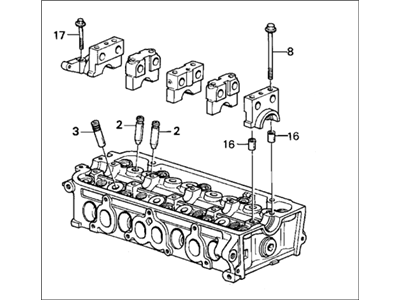

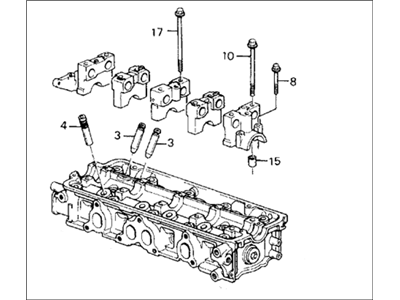

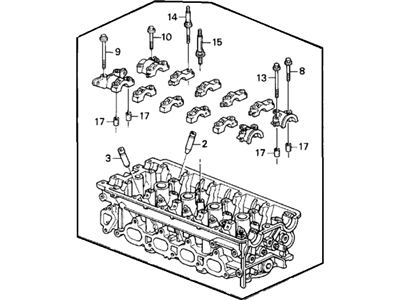

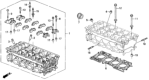

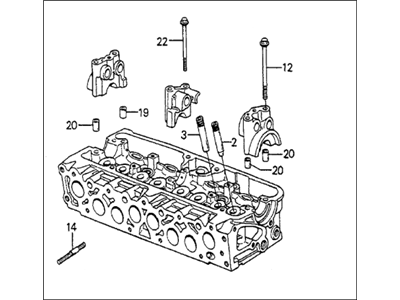

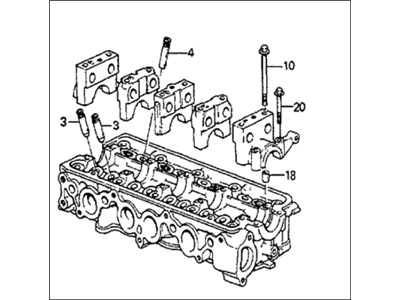

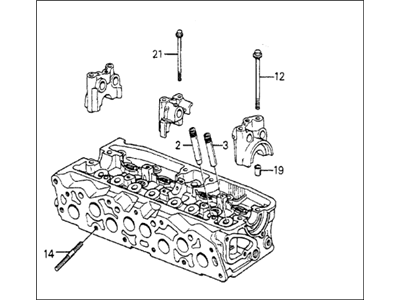

- Q: What are the key steps and precautions to take when removing and reinstalling a cylinder head on Honda Prelude?A:When lift-off a cylinder head, the first thing to remember is that extra time spent planning and in ensuring cleanliness will be rewarded; don't scrimp on cardboard boxes or on a good felt-tip pen for marking parts as they are removed. Be sure to have enough clear plastic bags with zippers that can seal for storage of the fasteners, know whether some fasteners can be reused or if you will have to replace them. Have used coolant and engine oil carrying sealable receptacles for the coolant and engine oil that may be drained during the procedure, pencil and a notepad will also be useful in sketching the positions of the cables, wire and brackets. Specific instructions toward their installation should be strictly adhered to every now and then to check whether lubri- In some cases, the kind of fastener to be used requires lubrication. At least, acquaint yourself with the equipment that will be used in the subsequent articles, as the majority of cylinder head parts are finely tuned in and must be cleaned and inspected before installation. Try not to let any two machined pieces touch one another, set components directly onto the ground or swap their positions. In the construction process, only wood or cardboard materials should be used to protect the machined parts more so the cylinder head. Before disconnecting the battery, record the radio's coded theft protection circuit number and after re-connecting the battery turn the steering wheel full lock-full unlock to reset the steering control unit. Cylinder No. 1 should be at TDC and there's a removal of the throttle cable BV, the ignition coil, and the electrical connectors with 2.2 L engine models, in addition to removing the negative cable of the battery and drain the coolant. There is recommended number and technique on how to remove the Intake Manifold, Exhaust Manifold, cylinder head bolts; to avoid warpage on those bolts they have to be loosened in a particular sequence. For installation it is important to ensure all surfaces of gasket are clean, check for warpage in the head gasket, and the new head gasket is installed when tightening the bolts they should be tightened in steps to the recommended torque setting. Perform the same process for 2.3L, 2.7L, and 3.0L engines as the correct order of disassembly and reassembly, leakage test, and ignition timing check shall increase.

Related Honda Prelude Parts

Browse by Year

2026 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head 1986 Cylinder Head 1985 Cylinder Head 1984 Cylinder Head 1983 Cylinder Head 1982 Cylinder Head 1981 Cylinder Head 1980 Cylinder Head 1979 Cylinder Head