×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Honda Parts

- Honda Accessories

My Garage

My Account

Cart

Genuine Honda Del Sol Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Cylinder Heads found

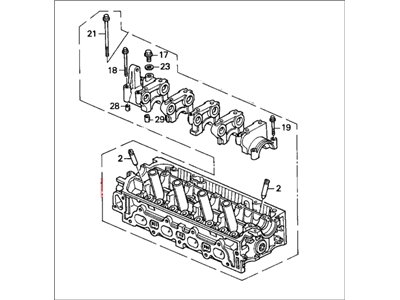

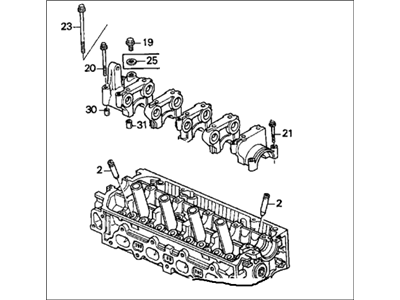

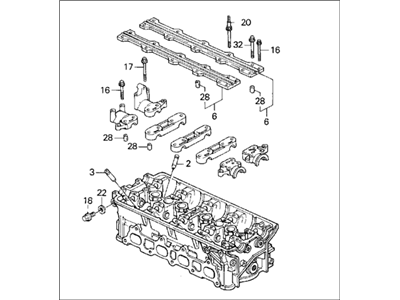

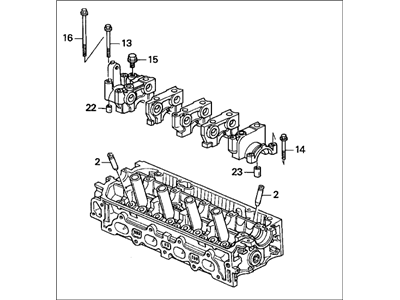

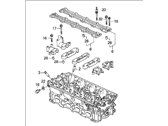

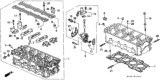

Honda Del Sol General Assembly, Cylinder Head

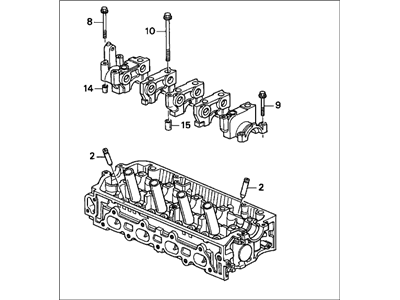

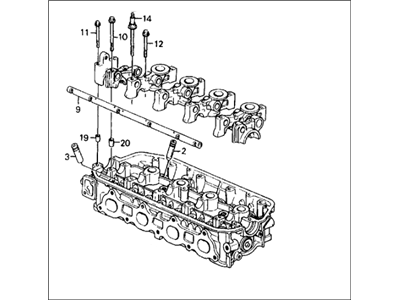

Part Number: 10003-P2T-G01$2538.00 MSRP: $3380.61You Save: $842.61 (25%)Honda Del Sol General Assembly, Cylinder Head

Part Number: 10003-P2T-G00$2538.00 MSRP: $3380.61You Save: $842.61 (25%)

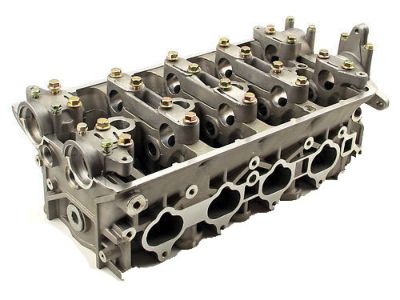

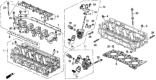

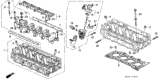

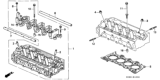

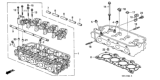

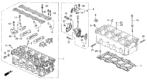

Honda Del Sol Cylinder Head

In search of affordable OEM Honda Del Sol Cylinder Head? Consider browsing through our extensive inventory of genuine Honda Del Sol Cylinder Head. Not only do we provide market-leading prices and a manufacturer's warranty, but we also pride ourselves on exceptional customer service and swift delivery.

Honda Del Sol Cylinder Head Parts Questions & Experts Answers

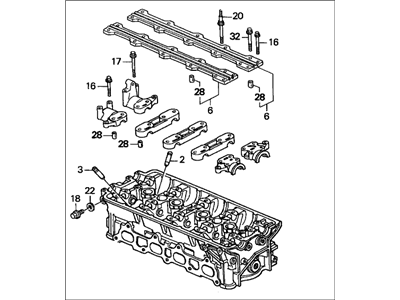

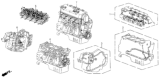

- Q: What precautions should be taken before beginning the cylinder head disassembly and inspection procedure on Honda Del Sol?A:Allow the engine to cool completely before beginning this procedure. Position the number one piston at Top Dead Center and disconnect the negative cable from the battery. The radio in your vehicle is equipped with an anti-theft system, so consult the relevant information before detaching the battery cable. Drain the cooling system and remove the spark plugs. Remove the Intake Manifold brace and Exhaust Manifold flange bolts; you may wish to detach the intake or exhaust manifold to make the cylinder head easier to handle. Remove the Valve Cover and the distributor, including the cap and wires. Remove the Timing Belt, Rocker Arm assembly, and the Camshaft. Loosen the head bolts in 1/4-turn increments until they can be removed by hand, working in a pattern that's the reverse of the tightening sequence to avoid warping the head. Note where each bolt goes for reinstallation. Lift the head off the engine, prying between the power steering pump bracket and the engine block if necessary, and set the head on blocks of wood to prevent damage to the gasket sealing surfaces. Cylinder head disassembly and inspection procedures are important, and it's advisable to check the head for warpage even if just replacing the gasket. The mating surfaces of the cylinder head and block must be perfectly clean when the head is installed. Use a gasket scraper to remove all traces of carbon and old gasket material, then clean the mating surfaces with lacquer thinner or acetone. If there's oil on the mating surfaces when the head is installed, the gasket may not seal correctly and leaks may develop. Stuff the cylinders with clean shop rags to keep out debris and use a vacuum cleaner to remove material that falls into the cylinders, being careful not to damage the aluminum surfaces. Check the block and head mating surfaces for nicks, deep scratches, and other damage; slight damage can be removed with a file, while excessive damage may require machining. Use a tap of the correct size to chase the threads in the head bolt holes, and run a die down the threads of each head bolt to remove corrosion and restore the threads. Place a new gasket on the block, ensuring any markings indicating installation orientation face UP, and apply sealant to the edges of the timing chain cover where it mates with the engine block before setting the cylinder head in position. Lubricate the threads and seats of the cylinder head bolts with clean engine oil, then install and tighten them in a specific sequence, in two stages and to the specified torque. Attach the camshaft sprocket to the camshaft and install the timing belt. Reinstall the remaining parts in the reverse order of removal, refill the cooling system, and check all fluid levels. Rotate the crankshaft clockwise slowly by hand through two complete revolutions, stopping to re-check the camshaft timing if any resistance is felt, as the valves may be hitting the pistons. Start the engine and check the ignition timing, then run the engine until normal operating temperature is reached, checking for leaks and proper operation.